PTFE Yarn with low heat-shrinkage stands out for its ability to maintain strength and shape in extreme conditions. Industries that rely on this advanced material include:

·Aerospace

·Automotive

·Industrial manufacturing

These sectors drive a market valued at $1.2 billion USD in 2022, with an expected annual growth rate of 6.8% through 2030. This yarn consistently delivers durability and stability where demanding environments require top performance.

Core Properties of PTFE Yarn

Low Heat-shrinkage Explained

PTFE Yarn demonstrates exceptional stability when exposed to heat. Manufacturers design this material to retain its original dimensions even after repeated heating cycles. This low heat-shrinkage property ensures that woven products maintain their shape and size, which is critical in applications like gaskets, seals, and filtration fabrics. Engineers rely on this stability to produce components that fit precisely and perform reliably, even in environments with fluctuating temperatures. The ability to resist shrinkage under heat sets PTFE Yarn apart from many traditional fibers, reducing the risk of product failure due to dimensional changes.

Tip: Low heat-shrinkage in PTFE Yarn helps prevent warping or deformation, ensuring consistent performance in demanding industrial settings.

Chemical Resistance

PTFE Yarn stands out for its remarkable chemical resistance. It remains virtually inert when exposed to most acids, bases, and solvents. This property makes it a preferred choice in industries where contact with corrosive substances is common, such as chemical processing and power generation. Unlike polyester and aramid yarns, which can degrade in harsh environments, PTFE Yarn maintains its integrity and performance.

| Material | Chemical Resistance |

|---|---|

| PTFE | Virtually chemically inert; resistant to most chemicals, only affected by a few, such as elementary alkali metals like sodium. |

| Polyester | Lower chemical resistance; susceptible to damage in harsh environments. |

| Aramid | Similar to polyester; does not match PTFE’s level of resistance in corrosive conditions. |

High-temperature Tolerance

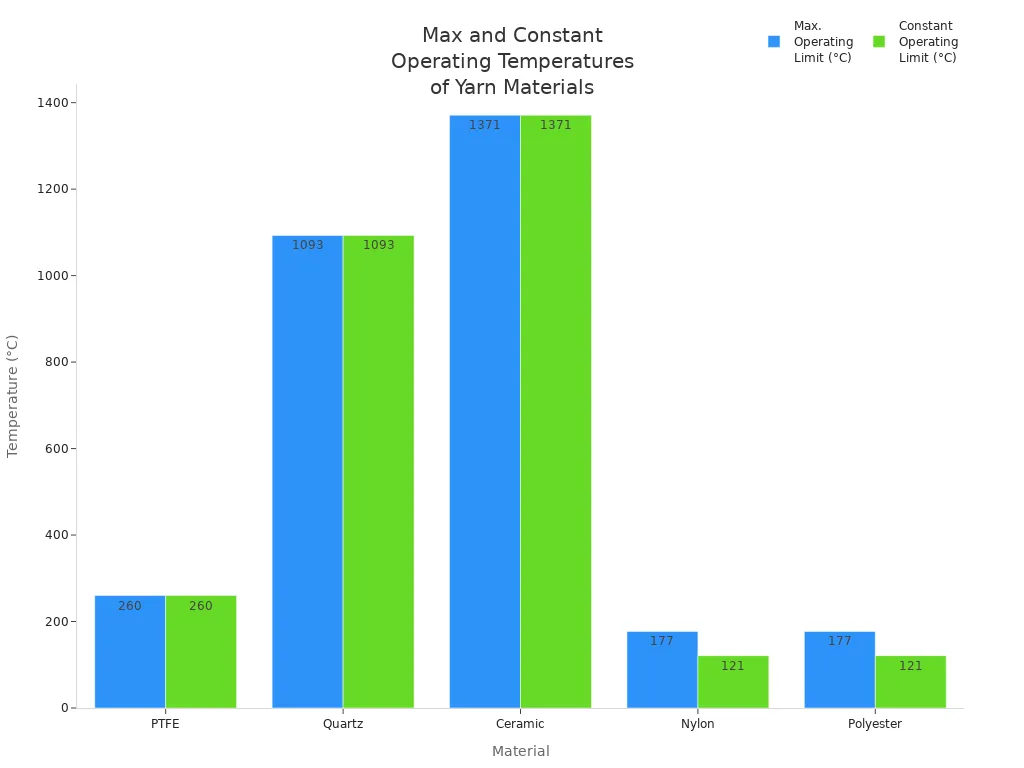

PTFE Yarn delivers outstanding performance at elevated temperatures. It can operate continuously at temperatures up to 260°C (500°F), which surpasses the limits of nylon and polyester. This high-temperature tolerance allows PTFE Yarn to serve reliably in environments where heat exposure is constant, such as aerospace and industrial manufacturing.

PTFE Yarn does not match the extreme heat resistance of quartz or ceramic fibers, but it outperforms most synthetic yarns used in industry. However, repeated exposure to high temperatures can reduce the tensile strength of PTFE Yarn. The intensity and duration of heat exposure play a significant role in this process. Despite some loss in mechanical properties, the thermal protective performance of PTFE Yarn remains stable, making it suitable for protective gear and high-stress applications.

UV Stability and Weather Resistance

PTFE Yarn demonstrates outstanding resistance to ultraviolet (UV) radiation and harsh weather conditions. This property makes it a preferred material for outdoor applications, where exposure to sunlight and environmental stress can degrade conventional fibers. Manufacturers subject PTFE-based products to rigorous testing to confirm their UV stability. These tests include QUV accelerated weathering and outdoor exposure assessments.

·QUV accelerated weathering tests simulate long-term sunlight exposure.

·Outdoor weathering tests validate performance in real-world conditions.

·The xenon-arc weathering meter, as outlined in ISO 4892-2, measures the effects of UV exposure on PTFE Yarn.

·Weathering simulation tests follow DIN/EN ISO 4892 standards.

| Test Method | Standard Reference |

|---|---|

| Xenon-arc weathering meter | ISO 4892-2 |

| Weathering simulation tests | DIN/EN ISO 4892 |

These standardized procedures ensure that PTFE Yarn maintains its integrity and color even after prolonged UV exposure. In comparative studies, PTFE-based yarns consistently achieve high client satisfaction rates after more than 5,000 hours of UV exposure. This performance matches or exceeds other leading industrial yarns.

| Yarn Type | UV Exposure Hours | Client Satisfaction Rate |

|---|---|---|

| PTFE | > 5000 | > 30% |

| Endnus | > 5000 | > 30% |

| Jiahe Taizhou | > 5000 | > 30% |

Note: High UV stability ensures that products made with PTFE Yarn retain their strength and appearance, even in outdoor or high-altitude environments.

Mechanical Strength and Durability

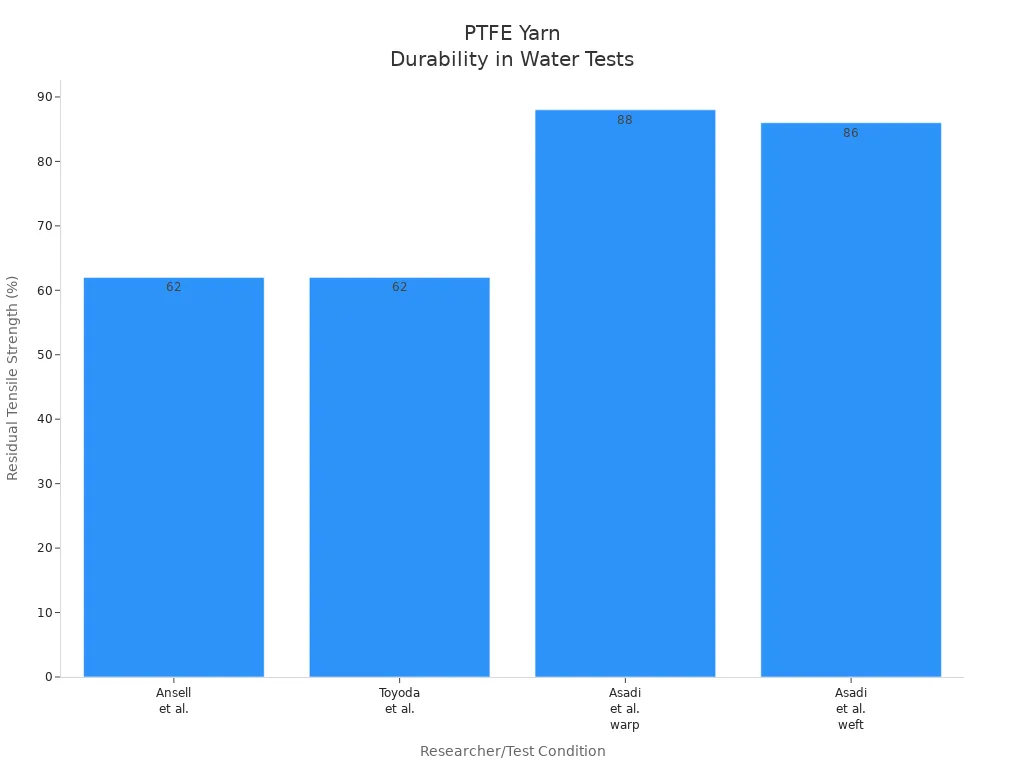

PTFE Yarn offers exceptional mechanical strength and long-term durability, making it suitable for demanding industrial applications. Researchers have evaluated its performance under various environmental conditions, including high humidity and temperature. These studies show that PTFE Yarn retains a significant portion of its tensile strength after prolonged exposure to moisture and heat.

| Researcher | Test Procedure | Results/Conclusions |

|---|---|---|

| Ansell et al. | Immersion in distilled water for 7 days at 85°C/85% RH | Retained tensile strength of about 62% of the original value; drying restored stiffness. |

| Toyoda et al. | Immersion at various temperatures for up to 14 days | Retained tensile strength at 90°C after 14 days was 62% for coated fabrics. |

| Asadi et al. | Water tests at room temperature for different soaking times | Residual tensile strengths were about 85% to 91% for warp and 82% to 89% for weft directions. |

These results confirm that PTFE Yarn maintains its mechanical properties even after exposure to challenging environments. The yarn resists degradation from water, heat, and humidity, which extends the service life of products made from it. This durability reduces the need for frequent maintenance or replacement, providing significant value in industrial settings.

Products that require consistent strength and reliability, such as seals, gaskets, and filtration fabrics, benefit from the robust performance of PTFE Yarn.

Key Advantages of PTFE Yarn in Industrial Use

Dimensional Stability in Harsh Environments

Industrial environments often expose materials to extreme temperatures, aggressive chemicals, and mechanical stress. PTFE Yarn maintains its original dimensions even when subjected to these harsh conditions. This dimensional stability ensures that components such as seals, gaskets, and filtration fabrics retain their precise fit and function over time. Engineers value this property because it reduces the risk of leaks or failures in critical systems. Products made with PTFE Yarn do not warp or deform, even after repeated thermal cycling or chemical exposure. As a result, industries can rely on consistent performance and reduced downtime.

Extended Service Life and Reduced Maintenance

PTFE Yarn offers exceptional resistance to wear, aging, and UV light. These qualities translate into a longer service life for industrial products and lower maintenance costs. The following table highlights how these advantages impact maintenance schedules and expenses:

| Advantage | Description |

|---|---|

| Long Service Life | Exceptional resistance to wear, aging, and UV light results in fewer replacements and lower maintenance costs. |

Many industries use PTFE packing in sealing applications for pumps, valves, and agitators. Its high chemical resistance and temperature stability make it suitable for demanding environments. Selecting the right PTFE packing proves crucial, as the wrong choice can lead to costly leaks and unscheduled downtime. This directly affects maintenance schedules and operational costs. By choosing PTFE Yarn, companies minimize the frequency of repairs and replacements, which helps maintain productivity and control expenses.

Tip: Regular inspection and proper selection of PTFE-based components further extend equipment life and reduce unexpected maintenance.

Consistent Performance Under Thermal and Chemical Stress

PTFE Yarn delivers reliable performance even under significant thermal and chemical stress. Its unique structure allows it to withstand repeated exposure to high temperatures and aggressive chemicals without losing strength or integrity. The following table compares the durability of different yarns under stress:

| Yarn Type | Durability Under Stress | Coating Thickness | Filament Structure |

|---|---|---|---|

| Yarn 1 | Lower durability, complete breakage observed | Thinner PTFE coating | Fewer, thicker filaments |

| Yarn 2 | Higher durability, only some filaments broke | Thicker PTFE coating | More, thinner filaments |

PTFE Yarn, especially when engineered with a thicker coating and finer filaments, demonstrates superior durability. This resilience ensures that products continue to function as intended, even in the most challenging industrial settings. Operators can trust that equipment using PTFE Yarn will maintain its performance, reducing the risk of unexpected failures.

·PTFE Yarn supports consistent operation in environments with fluctuating temperatures.

·It resists degradation from both chemical and thermal exposure, ensuring long-term reliability.

Customizability for Specific Applications

Manufacturers recognize that industrial environments demand materials tailored to unique requirements. They design PTFE Yarn to offer a high degree of customizability, ensuring optimal performance in specialized applications. This flexibility allows engineers and product developers to select yarn specifications that align with their project goals.

Key customization options include:

·Production in a wide range of colors for easy identification or coding within complex systems.

·Availability in specific denier and tex values, allowing precise control over yarn thickness and strength.

·Adjustment of filament structure and coating thickness to meet durability or flexibility needs.

·Custom packaging and spool sizes to fit different weaving or processing equipment.

These options enable companies to integrate PTFE Yarn seamlessly into their manufacturing processes, regardless of the complexity or scale of the application.

Industries across the globe benefit from custom-engineered PTFE solutions. The following table highlights several sectors and their specialized uses:

| Industry | Application |

|---|---|

| Textile Industry | High-performance fabrics for outdoor sports clothing, military uniforms, and protective clothing. |

| Filtration Industry | EPTFE-coated filter materials for air and liquid filtration in industrial systems. |

| Sealing Industry | Gaskets and seals for mechanical equipment and pipelines, especially in high-temperature applications. |

| Electrical Industry | Insulation for wires and cables, and components for electronic devices. |

| Medical Industry | Applications in vascular grafts and wound-dressing materials for tissue healing. |

Customization ensures that each industry receives a solution tailored to its operational challenges. This approach maximizes efficiency, safety, and product longevity.

Manufacturers continue to innovate, expanding the range of available options for PTFE Yarn. As industries evolve, the demand for specialized materials will only increase, making customizability a key factor in industrial success.

Industrial Applications of Low Heat-shrinkage PTFE Yarn

Sealing and Gasket Manufacturing

Manufacturers in the chemical, aerospace, and automotive sectors rely on low heat-shrinkage PTFE yarn for producing seals and gaskets that must perform under extreme conditions. This yarn maintains its shape and strength even after repeated exposure to high temperatures and aggressive chemicals. The dimensional stability of PTFE-based seals leads to higher processing yields and more consistent products. The following table highlights the advantages of PTFE yarn in this application:

| Advantage | Description |

|---|---|

| Chemical Resistance | Remains virtually inert, even in harsh chemical environments. |

| UV Resistance | Does not degrade under UV light, ensuring long-term durability. |

| Non-Flammability | High Limiting Oxygen Index (LOI) makes it non-flammable. |

| Low Friction | Self-lubricating surface reduces wear and eases installation. |

| Thermal/Electrical Insulation | Withstands high temperatures and provides excellent insulation. |

| Food and Medical Use | Approved for sensitive applications, including food and medical devices. |

PTFE yarn’s unique properties help prevent leaks and failures, making it a trusted choice for critical sealing applications.

Cable and Wire Insulation

Engineers use PTFE yarn to insulate cables and wires in demanding industrial environments. This material resists a wide range of corrosive substances, including acids and solvents. It operates effectively from -200°C to 327°C, maintaining its insulating properties in both freezing and high-heat conditions. PTFE yarn also provides a low dielectric constant and high dielectric strength, which ensures safe and reliable electrical performance. Its toughness allows it to withstand mechanical stress and vibration, while the non-stick surface supports smooth material flow during installation.

·Resists corrosion from chemicals and solvents

·Maintains integrity across extreme temperature ranges

·Provides strong electrical insulation for safety

·Withstands mechanical stress and vibration

·Supports smooth installation due to low friction

Aerospace and Automotive Components

PTFE yarn plays a vital role in aerospace and automotive engineering. Designers incorporate it into composite materials to enhance mechanical strength and reduce wear. Research shows that composites using PTFE yarn and aramid fibers achieve a 44% reduction in wear rate compared to traditional materials. This improvement leads to longer-lasting components and increased safety in high-performance vehicles and aircraft. The yarn’s ability to resist heat, chemicals, and mechanical stress makes it ideal for demanding applications such as engine seals, hoses, and protective fabrics.

The use of PTFE yarn in these sectors supports innovation and reliability, helping manufacturers meet strict industry standards.

Air Filtration and Environmental Systems

PTFE yarn plays a crucial role in modern air filtration and environmental systems. Engineers select this material for its ability to maintain performance in the presence of aggressive chemicals and fluctuating temperatures. PTFE yarn ensures that filtration media remain stable and effective, even after prolonged exposure to harsh industrial environments.

The following table highlights the key properties and benefits of PTFE yarn in these applications:

| Property | Benefit |

|---|---|

| High chemical resistance | Maintains performance under harsh conditions, ensuring longevity. |

| Durability | Reduces the need for frequent replacements, lowering operational costs. |

| Low pressure drops | Leads to reduced energy consumption, enhancing overall efficiency. |

| High porosity | Allows for precise separation of contaminants, improving air quality. |

| Long service life | Minimizes maintenance time and costs, contributing to operational savings. |

Operators in power plants, waste-to-energy facilities, and manufacturing plants rely on PTFE yarn to deliver clean air and protect sensitive equipment. The yarn’s high porosity enables precise contaminant separation, while its durability reduces downtime and maintenance expenses. These advantages make PTFE yarn a preferred choice for sustainable and cost-effective filtration solutions.

Electronics and Outdoor Fabrics

PTFE yarn offers significant advantages in electronics and outdoor fabric applications. Its exceptional durability and resistance to environmental stressors set it apart from conventional materials.

| Benefit | Description |

|---|---|

| Exceptional Durability | PTFE fibers can last 10–20 years in harsh conditions, outperforming traditional materials. |

| Chemical Inertness | They resist degradation, maintaining structural integrity without aging or embrittlement. |

| Reduced Maintenance Costs | Applications like seals see up to 30% reduction in maintenance costs due to fewer replacements. |

Outdoor jackets and technical fabrics often use PTFE yarn for waterproofing and breathability. The material’s durability means fewer replacements, which benefits both users and the environment. Expanded PTFE (ePTFE) also improves airflow, preventing overheating during physical activities. These features make PTFE yarn a top choice for manufacturers seeking long-lasting, high-performance solutions in electronics and outdoor products.

PTFE Yarn Compared to Other Industrial Yarns

PTFE vs. Polyester Yarn

PTFE yarn and polyester yarn serve different roles in industrial applications. PTFE yarn offers superior chemical resistance and withstands higher temperatures. Polyester yarn, while cost-effective and widely available, cannot match the durability or stability of PTFE in harsh environments. Many engineers choose PTFE for applications that demand resistance to acids, bases, and solvents. Polyester yarn often finds use in less demanding settings, such as general textiles or packaging.

| Property | PTFE Yarn | Polyester Yarn |

|---|---|---|

| Chemical Resistance | Excellent | Moderate |

| Heat Tolerance | Up to 260°C | Up to 150°C |

| UV Stability | Outstanding | Moderate |

| Cost | Higher | Lower |

PTFE yarn maintains its properties where polyester may degrade, especially under chemical or thermal stress.

PTFE vs. Aramid and Other High-performance Yarns

Aramid yarns, such as Kevlar, provide high tensile strength and are known for their cut resistance. However, PTFE yarn excels in chemical inertness and temperature stability. While aramid fibers can degrade when exposed to strong acids or UV light, PTFE yarn remains stable. Other high-performance yarns, like PBO or glass fiber, may offer specific advantages, but PTFE stands out for its balance of chemical, thermal, and weather resistance.

·Aramid: High strength, moderate chemical resistance, sensitive to UV.

·Glass fiber: Good heat resistance, brittle, less flexible.

·PTFE: Balanced performance across multiple demanding criteria.

Performance Differences in Heat-shrinkage

Heat-shrinkage can impact the dimensional stability of industrial yarns. PTFE yarn demonstrates minimal shrinkage, even after repeated heating cycles. Polyester and aramid yarns may shrink or deform when exposed to high temperatures, which can compromise product integrity. Manufacturers value PTFE yarn for its ability to retain shape and size, ensuring reliable performance in precision applications.

Minimal heat-shrinkage in PTFE yarn leads to fewer product failures and longer service life.

PTFE Yarn stands out in modern industries for its unmatched stability, reliability, and longevity.

·It offers chemical resistance, high-temperature tolerance, UV stability, and minimal shrinkage.

·These features ensure consistent quality and performance in the most demanding environments.

Choosing advanced materials like PTFE Yarn helps companies achieve long-term success and operational excellence.

FAQ

What industries benefit most from PTFE yarn with low heat-shrinkage?

Aerospace, automotive, chemical processing, filtration, and electronics industries use PTFE yarn. These sectors require materials that maintain stability, resist chemicals, and perform reliably under extreme conditions.

How does PTFE yarn compare to other synthetic yarns in durability?

PTFE yarn outperforms polyester and aramid yarns in chemical resistance, heat tolerance, and UV stability. The table below highlights key differences:

| Yarn Type | Chemical Resistance | Heat Tolerance | UV Stability |

|---|---|---|---|

| PTFE | Excellent | Up to 260°C | Outstanding |

| Polyester | Moderate | Up to 150°C | Moderate |

| Aramid | Good | Up to 200°C | Sensitive |

Can PTFE yarn be customized for specific applications?

Manufacturers offer PTFE yarn in various deniers, colors, and filament structures. This flexibility allows engineers to select the best option for their project requirements.

Is PTFE yarn suitable for outdoor use?

PTFE yarn resists UV radiation and harsh weather. Outdoor fabrics, filtration systems, and cable insulation benefit from its long-lasting performance.

Tip: PTFE yarn maintains strength and color even after years of outdoor exposure.

What is the maximum operating temperature for PTFE yarn?

PTFE yarn operates reliably up to 260°C. It retains mechanical properties and dimensional stability at high temperatures, making it ideal for demanding environments.

Post time: Jan-30-2026