ePTFE Membrane for Air Filtration, Clean Room & Dust Collection

Product Introduction

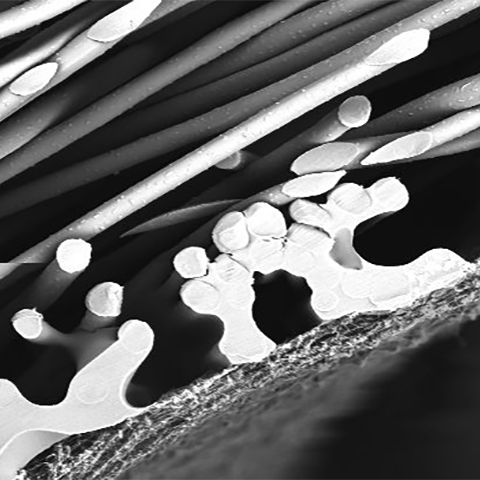

The microporous membrane has a biaxially oriented 3D fiber network structure, boasting a micron-equivalent aperture with high efficiency and low resistance. Compared to depth filtration, the surface filtration by PTFE membrane can effectively capture dust, and the dust cake can be easily pulsed off due to the smooth surface of PTFE membrane, resulting in lower pressure drop and longer service life.

ePTFE membranes can be laminated onto various filter media such as needle felts, glass woven fabrics, polyester spunbond, and spunlace. They are widely used in waste incineration, coal-fired power plants, cement plants, carbon black production facilities, boilers, biomass power plants . HEPA grade ePTFE membrane is also used in clean rooms, HVAC systems and vacuum cleaners and so on.

JINYOU PTFE Membrane Features

● Expanded micro-porous structure

● Bi-directional stretching

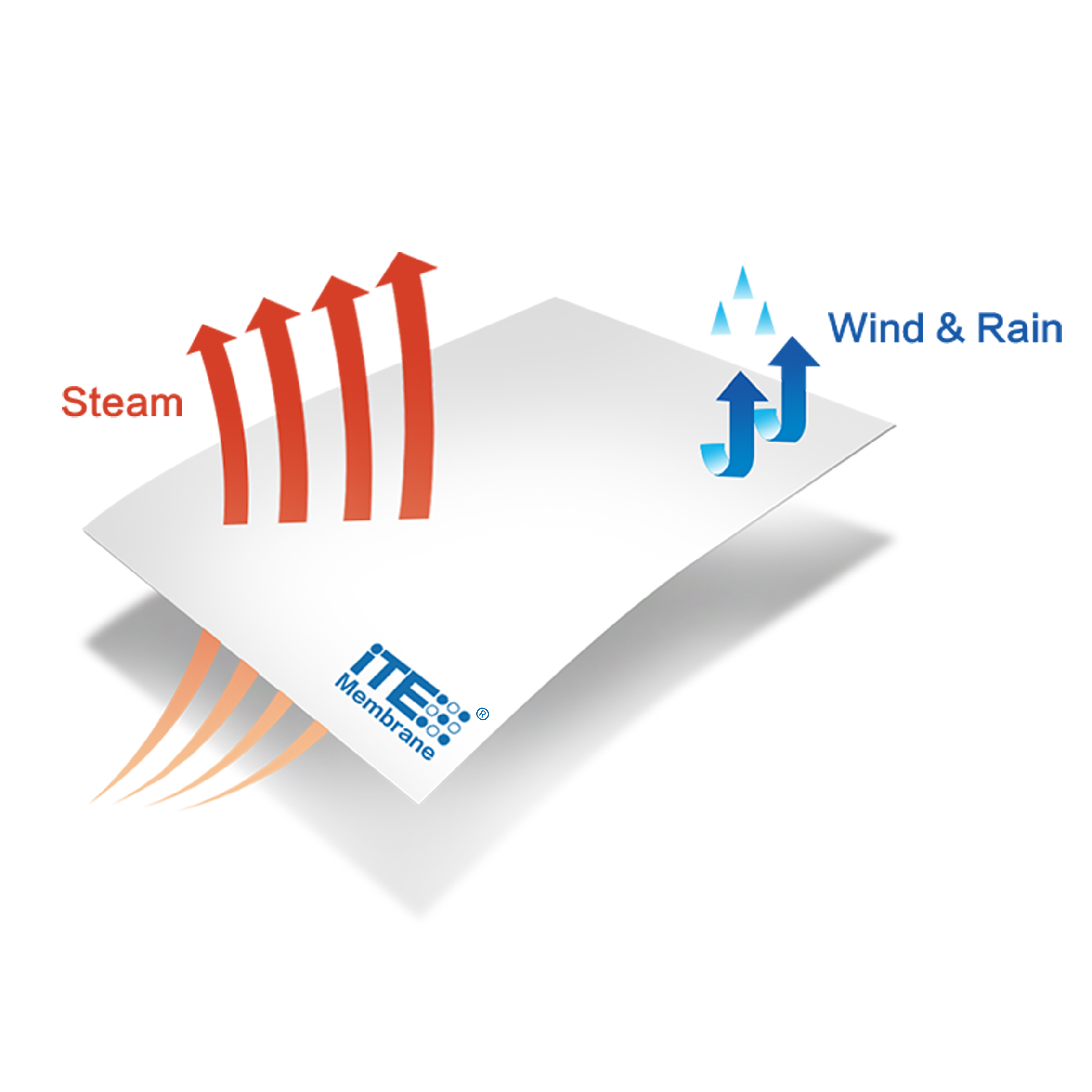

● Chemical Resistance from PH0-PH14

● UV Resistance

● Non-aging

JINYOU Strength

● Consistency in resistance, permeability and breathability

● High efficiency and low pressure drop in air filtration with superior VDI performance.

● 33+years production history with varieties of ePTFE membrane for different application

● 33+ years membrane lamination history with varieties of lamination technologies

● Customer-tailored