ePTFE Gasket Sheet with High Versatility to Various Flanges

Material Composition and Application

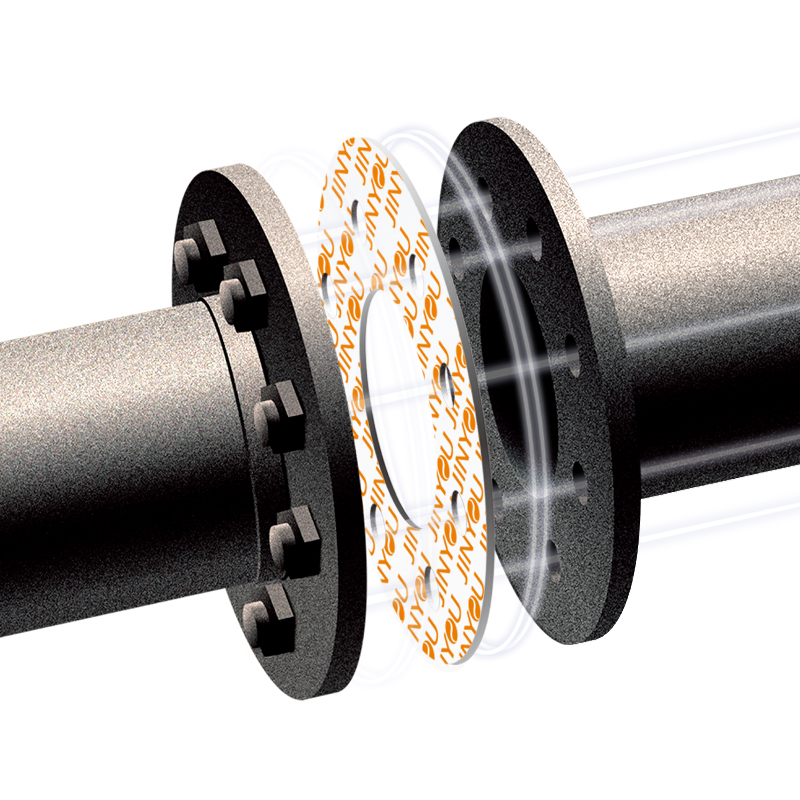

JINYOU®’ ePTFE sheet is capable of a wide service range in applications found throughout process industries. The patented UFG multilayer manufacturing method provides reliable sealability due to the low stress and exceptional dimensional stability characteristics the material possesses. This form of gasket material is processed by expanding 100% pure polytetrafluoroethylene (PTFE) into a highly fibrillated, bi-directional, soft, compressible gasket for longer life and trouble-free sealing. Its form-in-place versatility is perfect for flange surfaces that are worn, warped, or scored. The distinct compressibility of the UFG gasket enables it to effectively fill flange imperfections for a tight, leak-free seal. Unlike conventional PTFE materials which are prone to cold flow, JINYOU®’ ePTFE sheet has good creep resistance and bolt torque retention properties.

The JINYOU material has excellent chemical resistance with a pH range of 0 to 14, making it suitable for most mediums. The temperature service parameters range from -450°F (-268°C) to 500°F maximum/600°F spike (260°C/315°C) and pressure ranges from full vacuum to 3,000 psi (206 bar). These exceptional values are achieved without the need for filler materials like silica, barium sulfate, or hollow glass spheres. The Ultimate Flange Gasket material is ideal for both high-load metal flanged applications and low-load applications such as glass-lined steel, glass, and FRP (fiberglass reinforced plastic) piping and vessels. It does not support bacterial growth or cause product contamination and is FDA 21 CFR 177.1550 compliant.

JINYOU®’ ePTFE sheet has an unlimited shelf-life and is unaffected by normal environmental conditions.

Besides its standalone capabilities as an effective seal in highly corrosive applications, it is also one of the most widely used composites for the primary sealing element in semi-metallic gaskets such as spiral-wound, corrugated.

The JINYOU®’ ePTFE sheet solution reduces concerns of process safety and production downtime caused by the use of incorrect gasket material.

JINYOU ePTFE Sheet Features

● Expanded micro-porous structure

● Excellent chemical resistance from PH0-PH14

● Excellent sealing performance

● UV resistance

● Non-aging

JINYOU ePTFE Sheet Strength

● High adaptability for flanges with corrosion and uneven sealing surface.

● Ideal for use with more fragile piping systems.

● Easy to install and remove, anti-sticking for effortless flange surface cleaning.

● No embrittlement of the gasket in storage or in service.

● FDA, RoHS & REACH compliant.

● Chemically inert

● Impermeable.

● High temperature and pressure

● Seals at low stress loads

● Superior creep resistance

● 18+years of production history

● Thickness can be customer-tailored.

● 1.5m*1.5m, 1.5m*3m and 1.5m*4.5m are all available.